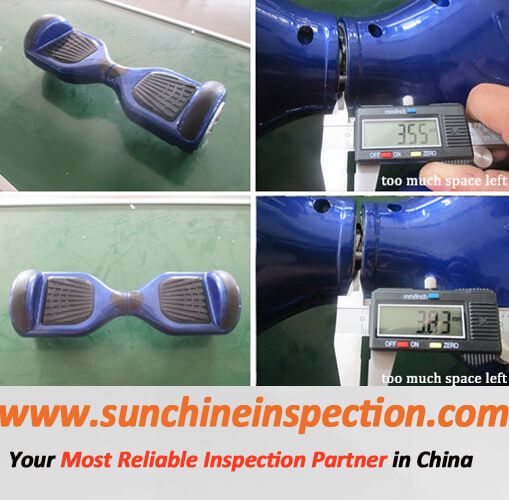

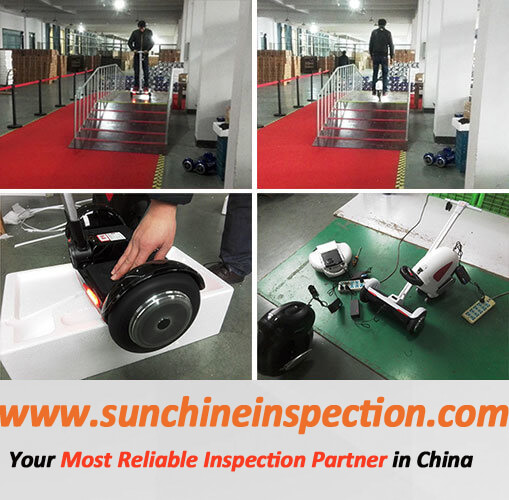

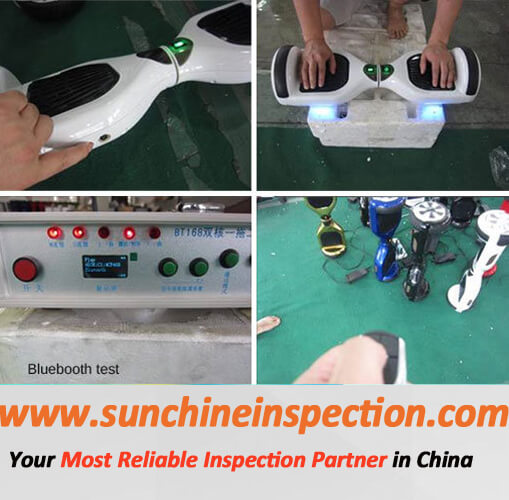

Some photos of the testing on product conducted by the full-time accredited inspector of Sunchine…

Electric Scooter Quality Check Quality Inspectors in Fujian Guangzhou Shenzhen Yangjiang Inspeciton Service

Relevant information:

Question: How is NDT different from QA/QC?

Answer 1: Do you know the difference in each? Quality Assurance and Quality Control are both part of quality management but both have distinct differences. Once you learn that, then you can do a comparative analysis, and determine how NDT corrolates. Time to do some homework.(Author: James Woodland From: Quora)

Answer 2: There is no much difference between NDT and QA/QC, NDT is non destructive testing used to test the materials with out disturbing the material and in different stages of the production. NDT is the sub branch of QA/QC. candidates who trained in NDT has number of job opportunities in India and abroad.(Author: Clara Hans From: Quora)

Answer 3: NDT, Non-Destructive Examination, is finding imperfections in materials or components that may affect their utility. The key feature is that NDT does this without damaging the item in the examination process.

QA, Quality Assurance, is a systematic documented process to achieve adequate product quality. NDT may be one of the steps in the process. If so, it is a QC (Quality Control) step, as could be a dimensional measurement.

Within the common area of Quality, all three terms denote quite different things.(Author: Mohan Babu From: Quora)

Thank you very much for your intrested in our service.

Sunchine team make the following proposal to help you control quality of chemical products.

Check product storing condition→Check whole quality→Check packing condition and marking→Randomly measure gross weight→Pick up samples from

finished products→Seal samples with Sunchine stickers and sign→ and send to lab for testing→Paste Sunchine sticker on each package→Send inspection and sampling report within 24 hours→Lab perform testing and send report after finishing→Check quanity again during loading process→Check packaging condition and marking randomly→Check empty container condition→Oversee loading process→Check 1/4, 1/2, 3/4 and full container→Check container No. and seal No.→Send Container loading check report for confirmation

Read more: https://www.sunchineinspection.com

This Post Has 0 Comments