Some clients have asked us “what is a certificate of conformity” over the years, and…

Product Specifications: What Tolerances for Measurements?

BY RENAUD ANJORAN

A client asked me, how to decide on tolerances to write on a drawing, when giving a technical file to a Chinese manufacturer?

I always suggest to importers that they define a product specification sheet. And they often struggle with setting the right tolerances. Many considerations need to be taken into account.

This is not a formal how-to guide, but I jotted down a few ideas.

First, you might not need to specify every dimension on your product. And on those dimensions you end up specifying, you might only need tolerances on a few of them (the “critical to quality” points).

Now let’s go through a few questions you might want to ask yourself.

For all products

- Can the manufacturing process achieve this tolerance? If you buy a forged part and you request precision in the hundreds of mm, it is simply not achievable. Be realistic.

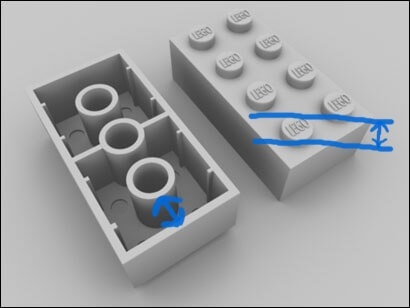

- Is it important for the product to “work”? For example, the dimensions shown below have to have relatively tight tolerances for the Lego bricks to assemble as expected.

- Is it competitive? Get the technical specifications of manufacturers of that same product in your country. That can be a good starting point.

- Is it allowed by the destination country’s standards? There are all sorts of standards to comply with, depending on the product like you are working on. Do your homework and be aware of those standards’ requirements, which often allow for a certain tolerance (for example in chemical composition, in noise, in vibration, and so on).

General consumer goods

- Does it make a difference in aesthetic terms if not all products are exactly the same size? When do the proportions of the different elements of the product become less pleasing to the eye? And, if several products are sold side by side (or piled up) on store shelves, how consistent do they need to appear?

For soft goods such as garments

- Are there several sizes? If, on measurement point A, size S is 10cm and size M is 12cm, the gap between them is 2cm. Half the gap is 1cm. The tolerance could be 1cm. Or maybe 0.5cm if the precision of the ‘fit’ is important for your brand (will the same customer need to find exactly the same ‘fit’ in several products they buy from your brand?).

- Does it make a difference in the construction of the product? For some garments, modelists often add a few measurement points to the size charts for that purpose only. They are supposed to help the manufacturer ‘get it right’, and also to spot issues that might not be caught easily.

What else should designers take into consideration?

Article Source: https://qualityinspection.org/drawing-tolerance-measurement/

This Post Has 0 Comments