Some clients have asked us “what is a certificate of conformity” over the years, and…

How a Factory Can Improve Quality

BY RENAUD ANJORAN

I bet you are tired of hearing your Chinese suppliers say “this is made by hand, so avoiding defects is impossible”.

So am I, because it’s so wrong.

Some small factories have decreased their defect rate below 50 parts per million (that’s 0.005%). Some of them, in Japan, employs housewives in the countryside, and their operations are all manual!

So, how do they get so close to zero defects? The answer is by applying a set of principles.

1. Faster production cycles help improve quality

Many factories have managed to reduce their cycle time (the time between starting a production run and getting some finished products) by 80% to 90%.

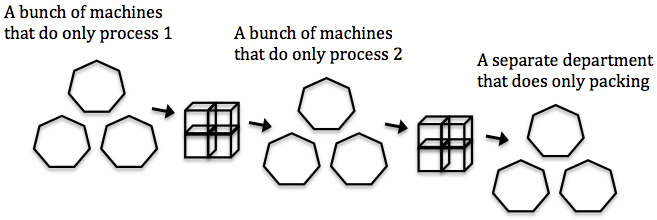

To simplify what happens, they get from this…

To this…

This is the best way to avoid widespread quality problems.

Why? Because finished products can be inspected/tested a few hours (maximum) after a production is launched, and the root cause(s) of a defect is much easier to find – the production batch is probably still in work-in-process status and “the trail is still hot”, as they say.

In contrast to that, I have seen many Chinese factories discover a widespread problem with a production batch after thousands of pieces had already passed through the faulty process. The trouble here is that because the production batch would have already been completed it is much more difficult to identify where the root cause of the problem took place — let alone fix the issue right away before it affects the whole batch.

2. Strong discipline improves adherence to standards

Putting a system in place is not the hard part, especially when ISO 9001-compliant quality systems are available on the internet and are (supposedly) ready to be used.

It doesn’t take months of work to place work instructions as well as photos of good and bad samples at each work station.

The hard part is training, coaching, and enforcing. There is no substitute for managers walking the shop floor every day and checking what the production staffs are doing.

What Chinese Managers tend to do however, is stay in their air-conditioned offices or meeting rooms. This lack of presence on the factory floor is quite unfortunate from both the factory’s and the buyer’s point of view.

When I first walk in a factory and I want to assess their quality level, I often carry out this simple 3-point test:

- Does the place seem to be in order? Do the operators wear appropriate clothes and protective equipment?

- Are there process controls and product checks, and is there a way to see if they have been done? (This could be written QC records or anything else that allows a supervisor to ensure it was checked.)

- If I ask them to describe the changes that had been made to one of their controlled documents (procedures, work instructions, forms…) over the last 3 months, do they need to “go and check” first?

If the answers to points 1 and 2 are YES and point 3 can be answered straight away, it tells me that there is some sort of structure and process that is being followed, which is a very positive sign.

3. The necessity for self-inspection

By self-inspection I mean the operators themselves do most of the quality control work. Not dedicated inspectors.

I don’t mean each worker should evaluate their own work – they lack the objectivity necessary for that.

The key is in successive inspection: I grab the part, I check it, I process it, and I put it down.

Here are the 3 basic principles that every worker MUST adhere to:

- We do not accept bad work

- We do not do bad work

- We do not pass on bad work

Does it conflict with the pay scheme so commonly applied in China (paying the operator based solely on the number of pieces he/she makes)? Yes, sure, but compensation structures can be changed.

Does it take more time for the operators to do these checks? Yes it can. And that’s a problem when a tough deadline needs to be met: operators might “exceptionally” choose to suspend self-inspection.

Fortunately, this extra time can be greatly reduced–and sometimes eliminated entirely–if you get creative, as we’ll see in next part.

4. The magic of mistake proofing and usability engineering

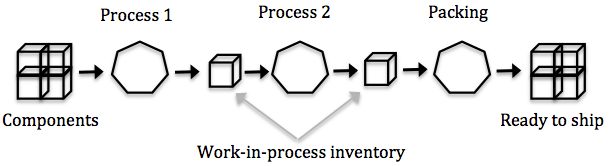

On your computer, have you ever inserted a cable (for example the power cord) in a wrong hole? It is impossible because they all have different shapes and sizes.

Some PC manufacturers have even color-coded the cables and the corresponding holes. Strictly speaking, that’s not mistake proofing because it does not always prevent mistakes. That’s usability engineering. But it still brings tremendous value.

Does it cost a lot of money? No. Is it effective? Yes!

Now, have you seen this type of thinking applied by a Chinese manufacturer?

- Would they think of asking the designer to make the holes different shapes/sizes? Probably not.

- Would they think of color-coding each hole and each cable? The probability is even lower.

Some manufacturers in Japan and in the West have become masters at mistake-proofing. You can find 240 pages of real examples that were implemented in factory settings here.

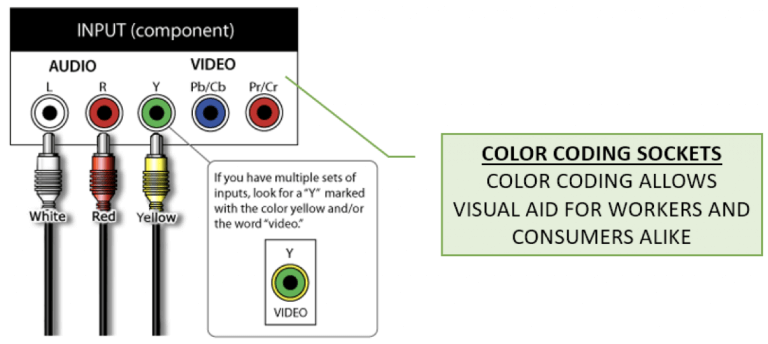

Here is a simple example (guide pins of different sizes, in a set of fixtures):

Could more than 4 principles be listed? Sure. I didn’t mention staff training and barely mentioned process control.

The 4 pieces of advice I listed above are those that generally make a big difference in a manufacturer’s quality level in a short amount of time. And the beauty is… It does not require any capital investment. Forget about automation, keep the same people, and show them how to work smarter!

Filed Under: Process Improvement

Article Source: https://qualityinspection.org/factory-improve-quality/

This Post Has 0 Comments