Some clients have asked us “what is a certificate of conformity” over the years, and…

Frequently Asked Questions about AQL

So, basically I have to authorize the factory to produce some defects?

In theory no. That’s why the AQL was renamed, from “acceptable quality level” to “acceptance quality limit”. It is a “limit” (and a loose one at that).

Here is what the ISO 2859 standard says:

“Although individual lots with quality as bad as the acceptance quality limit may be accepted with fairly high probability, the designation of an acceptance quality limit does not suggest that this is a desirable quality level. Sampling schemes […] are designed to encourage suppliers to have process averages consistently better than the AQL.”

Note that, in practice, using these statistics means you assume the factory cannot reasonably be expected to turn out 100% good quality.

Alternatively, you can choose an “acceptance on zero” plan. As soon as one defect is found, the inspection is failed. But you can impose this to suppliers only in situations where quality requirements are very high (in the auto industry, in aerospace…).

As a buyer, should I charge back the value of the defective products to the manufacturer?

This is not standard practice. The standard practice is actually to charge nothing back, as long as the inspection is passed.

However, as the buyer, make sure to add this provision in your contract with the supplier: if an inspection is failed, the supplier has to sort & rework the goods, and submit them to a new inspection (and the re-inspection costs are charged back to them).

Based on my AQL, I calculated the proportion of defects authorized. Why don’t they correspond to the maximum number of defects authorized?

It is true. In our example above, 2.5% of 200 samples is 5 samples, but we accept the goods even if 10 samples are found with a major defect.

Why this difference? There are heavy statistics behind this issue. To keep it simple, the producer’s risk is his risk of rejection (based on the random element when drawing the sample) even though his products (if they were all checked) would be accepted. That risk is about 5% in this standard. And, along the same logic, there is a consumer’s risk and is is around 10%. As you can see, this standard is favorable to the producer’s side.

Why not just say, ‘we’ll check 10% of the quantity’, or whatever percentage deemed appropriate?

This is discouraged, as clause 4.3.3 of the ISO 2859-10 standard explains:

Ad hoc sampling should not be used because it will lead to unknown risks that may be too high. Furthermore, there is no formal basis for either the acceptance or non-acceptance of the lot. Examples of ad hoc sampling include sampling of a fixed percentage of a lot or a convenience sample taken at haphazard times.

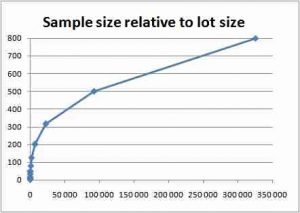

And here is one thing many buyers don’t realize. They say “inspect 10%”. But, as we go up in the total quantity, the proportion of products checked can decrease, for the same confidence in the inspection results.

As you can see in the chart below, if you follow the AQL tables, the number of samples to check (vertical axis) increases at a slower pace than the total quantity (horizontal axis).

How to choose an AQL limit for my products?

I explained it in details in this article. It depends on your distribution channel and your product’s end use. Note that your supplier might refuse AQL limits they estimate as too tight (i.e. too low).

What if we check quality before the whole batch is completed?

A reader asked me about this special case. A production of 500,000 pieces is under way. An inspection is done when 10% of the production is ready. With a normal inspection level II, what is the sample size?

- 800 because total production is 500,000?

- 500 because pieces that are ready is only 50,000?

The short answer is, the standard doesn’t really address this special case, as it was primarily designed for an inspection after an entire batch has been made.

My practical answer is, go with this option:

- 500 because pieces that are ready is only 50,000

Do we have to follow levels I, II, III, etc. and AQLs 1.0, 1.5, 2.5, etc.?

No. They are mere parameters that were thought to be applicable to most situations. For the sake of simplicity, it is better to have 3 tables with 10-20 columns each, than 50 tables with 100 columns each. Remember, all this was computed by hand in the 1930s, and inspectors had to look up the tables in paper form.

If you have a statistical software package such as Minitab, you can adjust the parameters as you see fit.

What are the “reduced” and “tightened” severities?

They are designed to be used in very specific situations, when a producer is particularly reliable, or on the contrary fails too often.

In practice, these severities are seldom used. Most inspections are done in normal severity. The rules to switch from normal to reduced or tightened are considered an important part of the standard (actually the evolutions of these rules constituted the main changes from MIL-STD 105A and MIL-STD 105E) but can be ignored.

Jim Bossert wrote this in the Feb. 2016 issue of Quality Progress:

You can use any plan without using the switching rules, but you do run the risk of not meeting the alpha risk in the end. These plans were developed to be used, as documented.

A normal plan is generally used and the switching rules come in when the clearance number has been obtained.

Some processes may never switch. If you choose a plan that is tightened or reduced to start with, you potentially will either spend too much on inspection (tightened) or risk having a bad product go to the customer (reduced).

It is a business decision for you to make if your customer is not demanding it. The switching rules are there to protect the producer when the product is running well or it has problems.

What are the limits of a quality control approach based on random sampling and AQL limits?

A: There are several limits:

1. An AQL limit is a target rather than a maximum. The buyer might have a nasty surprise when receiving a batch of products that “passed” the inspection.

2. A statistical QC approach does nothing to reduce the defects in the first place.

Can’t I just do my own sampling plan?

Sure. If you have a math background, you know that you’ll need to use a hypergeometric distribution (since samples are taken from the lot at random, are checked, and not put back into the lot until the end of the inspection). Specialized software like Minitab can help you a lot here.

If you want to avoid statistics altogether, your limits on the numbers of defects will not make much sense, but they might “feel” right intuitively and it might make you more comfortable… Just be aware of their shortcomings.

Make sure you get the supplier’s agreement on your plan. This might be the hardest thing to achieve!

Is there a more efficient way of checking quality of finished products?

There are many ways of drawing samples and checking their quality.If you don’t mind a more dynamic inspection plan, where the number of samples to check can’t be predicted in advance, you might want to follow a multiple-sampling plan, or even a sequential sampling plan. On average, for the same confidence in the decision, fewer samples will need to be checked.

Where can I learn more about the AQL?

If you really want to understand the concept of the AQL, you should spend about 20 minutes (total) watching these 3 videos on Youtube.

This Post Has 0 Comments