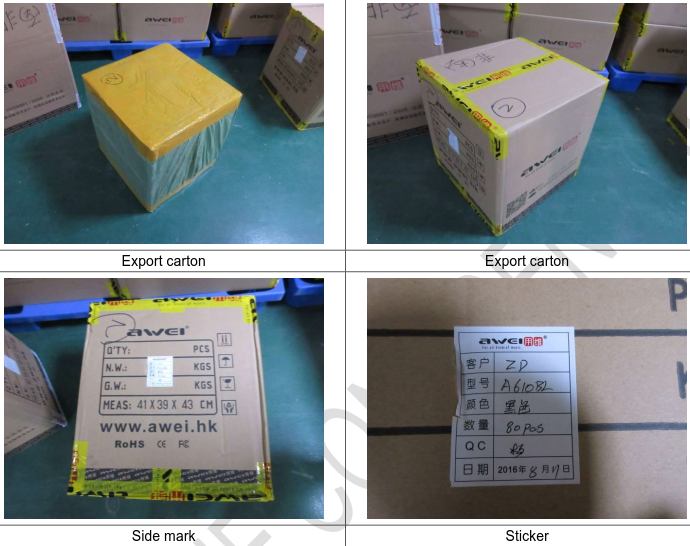

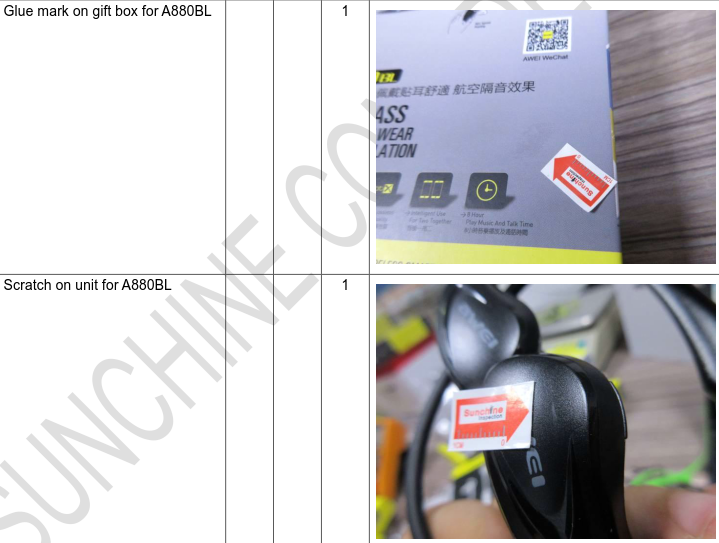

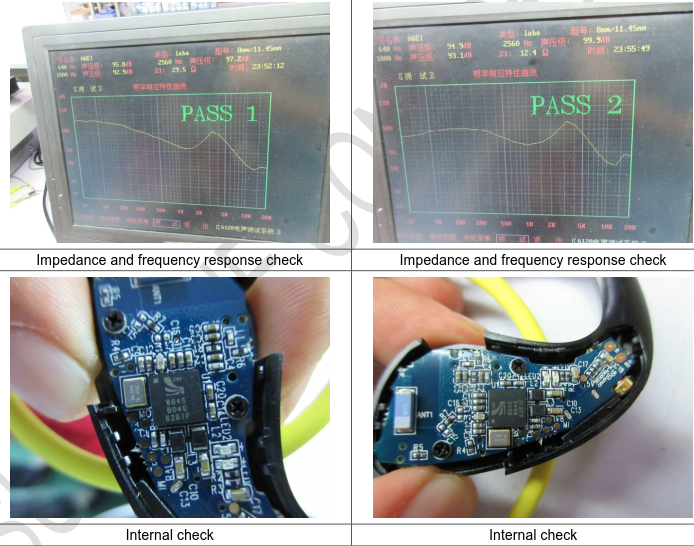

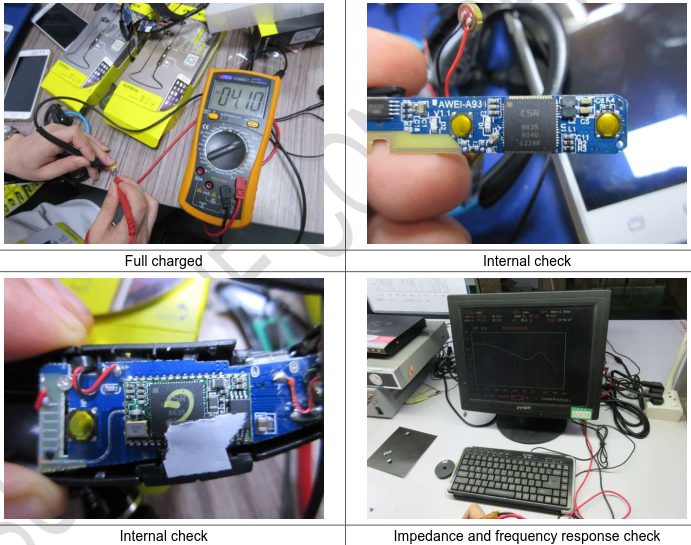

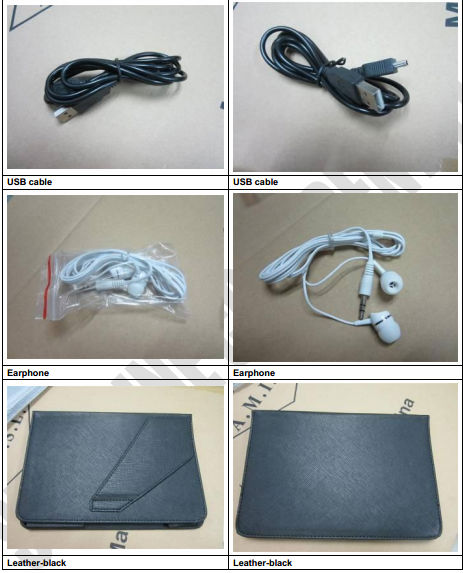

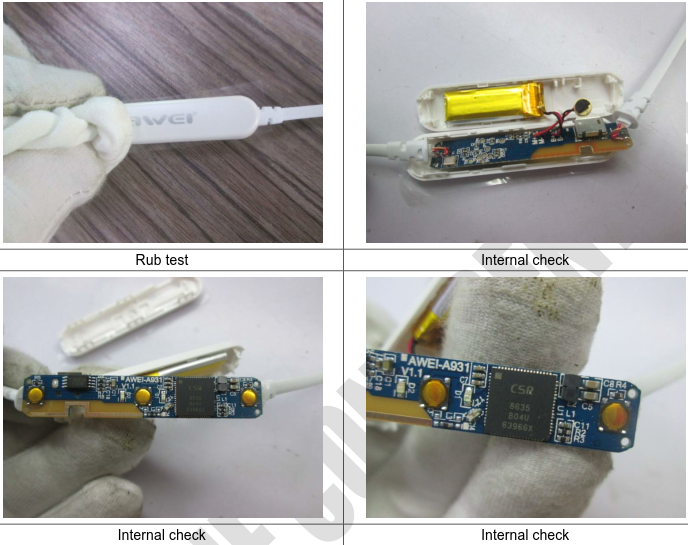

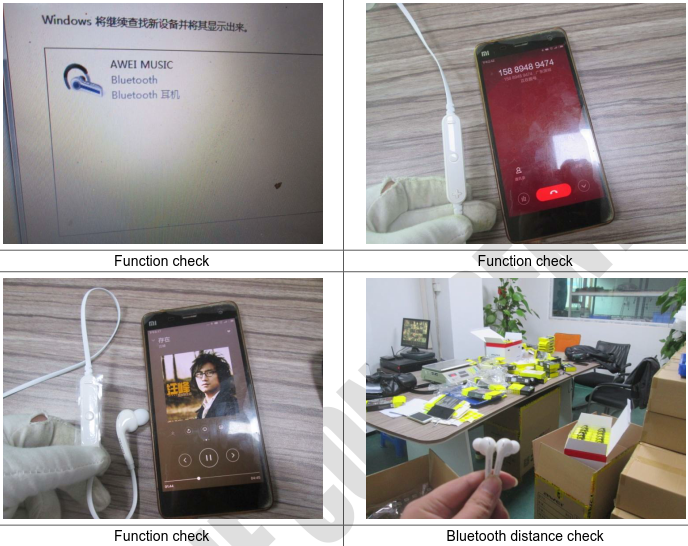

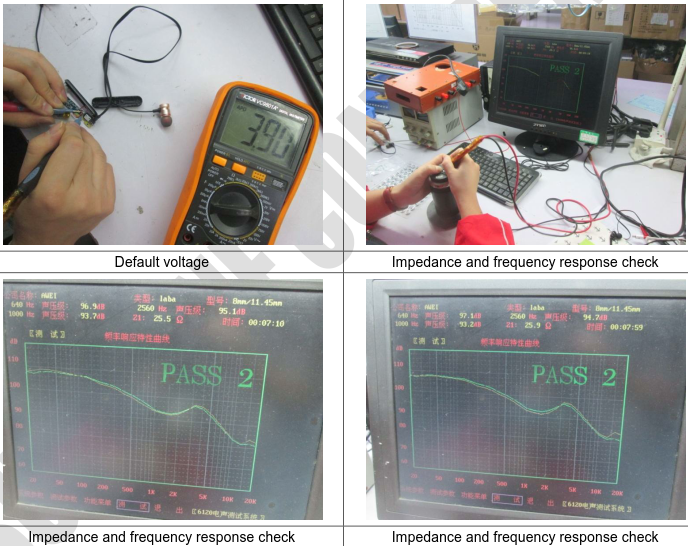

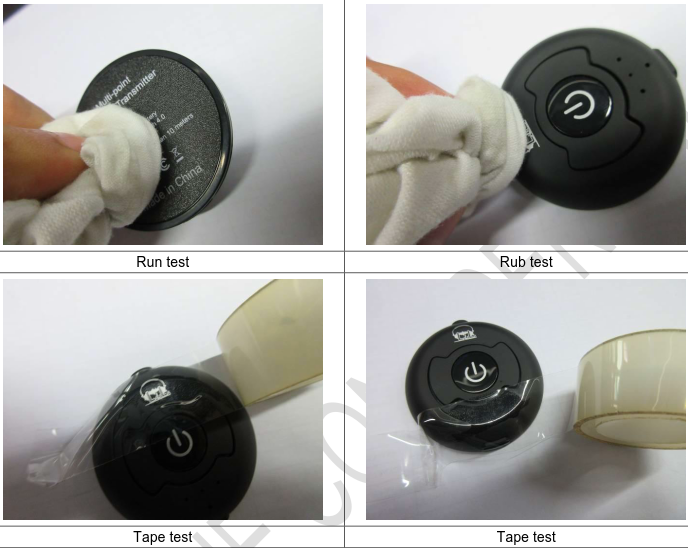

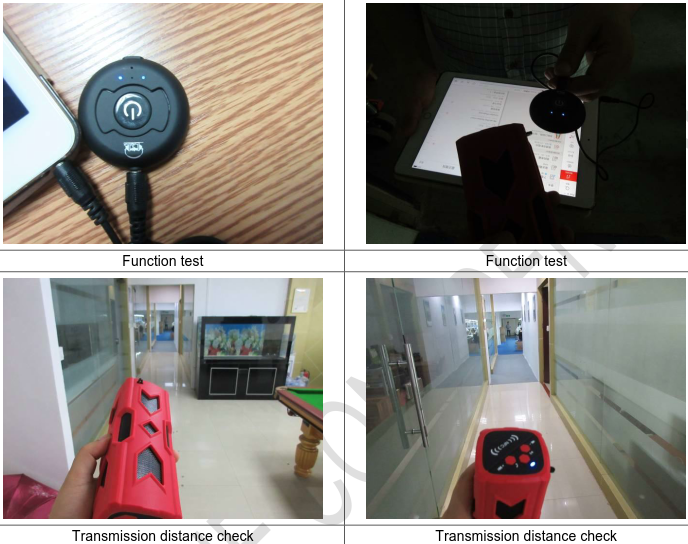

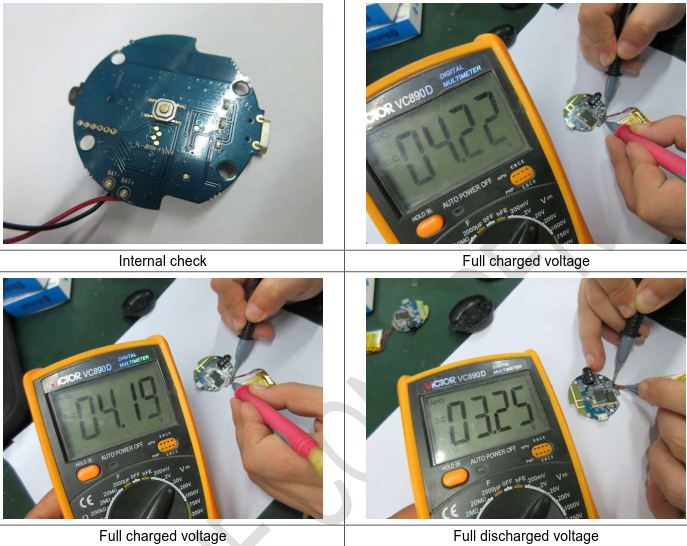

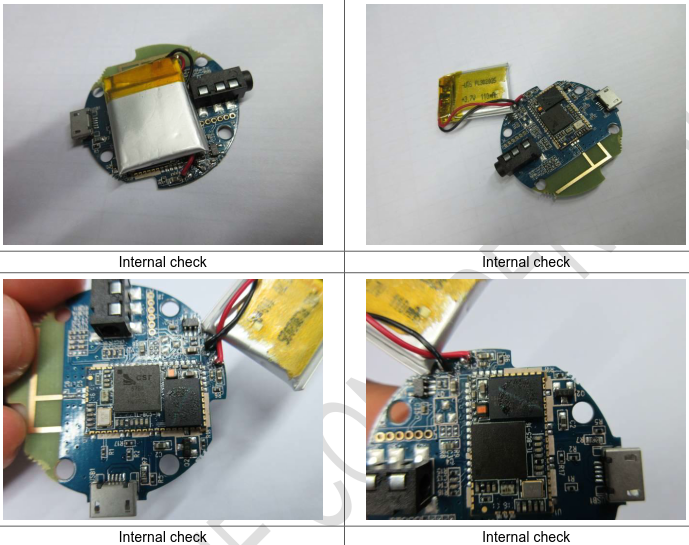

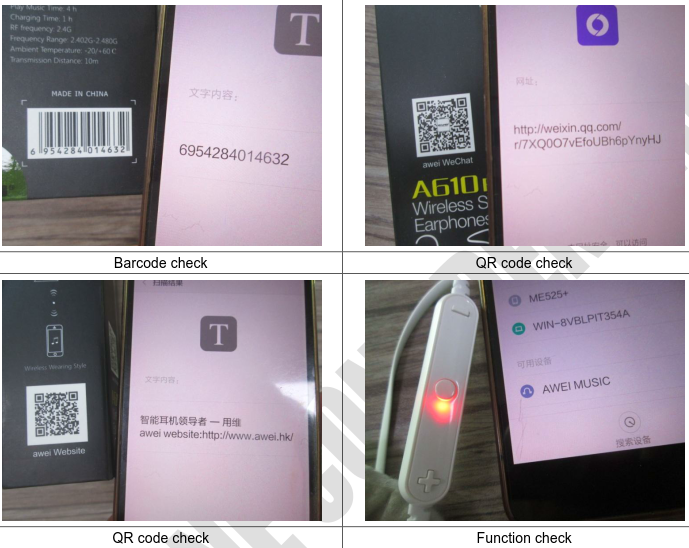

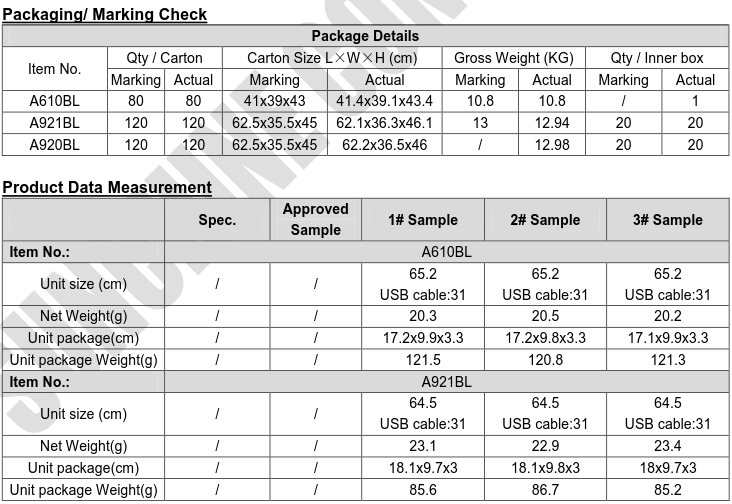

Some photos of the testing on product conducted by the full-time accredited inspector of Sunchine…

Bluetooth Earphone Quality Checking Service In Hongkong Taiwan Shenzhen Guangzhou Business Inspection Service

Relevant information:

Question: What is the importance of quality control checks in product design?

Answer 1: We all make mistakes for a wide variety of reasons, sometimes its just a misunderstanding of what is actually needed by the consumer, other times is just a typo that hides to jump out later at a more or less opportune moment.

Quality checks gives the development team a chance to look at the product from a usage perspective and check to see if the base or primary functions are working as expected and to be a check to see if the functions are the right ones for the consumers.

Its best if these can be automated because most of these checks will pass most of the time. But, the hope is that a small change that breaks some function or assumption of the code will be caught by at least one of the checks and fixed before it causes major damage to a customer or group of customers.

A side effect of this is if you have lots of “not so good” quality checks then you spend too much time chasing things that are problems with the checks rather than catching actual problems with the product as used by the consumers. (Author: Clark W. Johnson, From: Quora)

Answer 2: During product design process, No finished product then no quality control. It is better to call quality design.Quality design is part of product design. (Author: Dave Zeng, From: Quora)

This Post Has 0 Comments