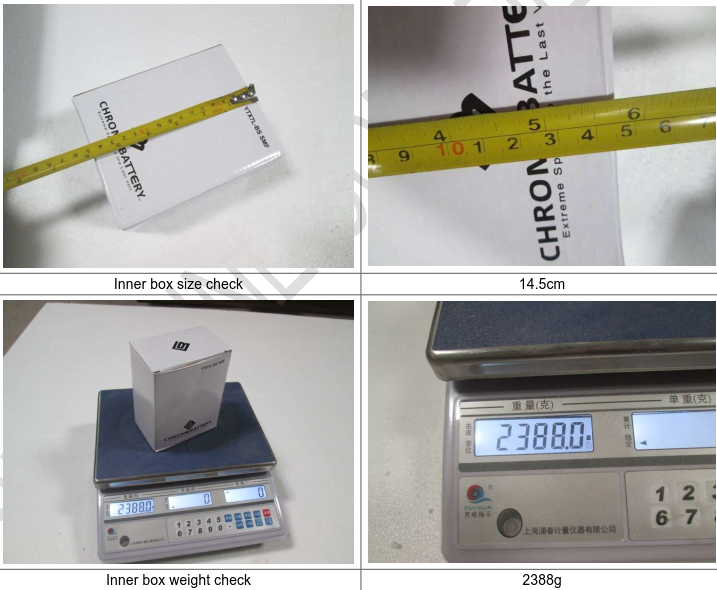

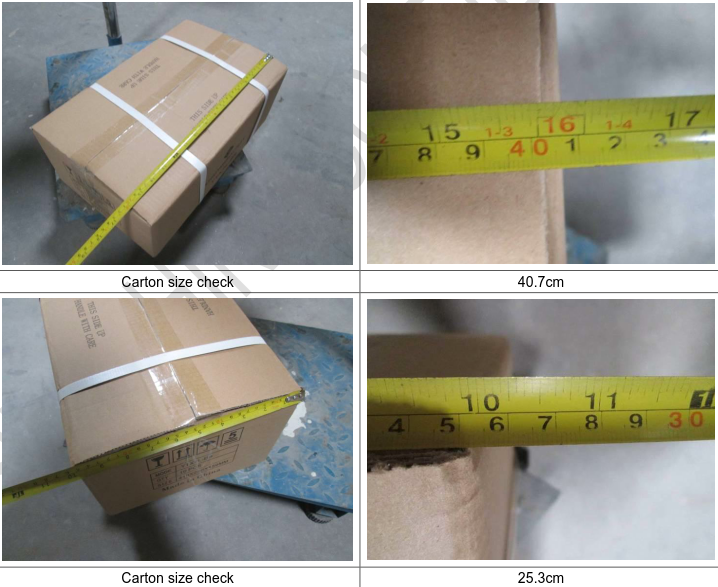

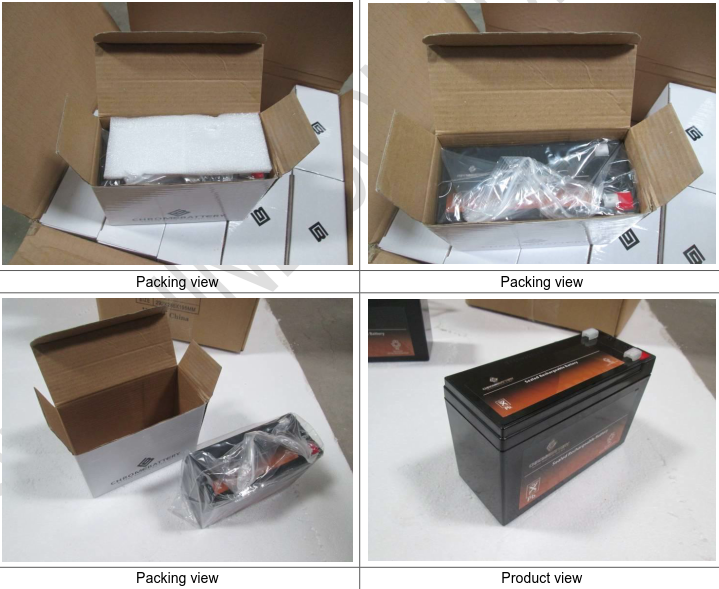

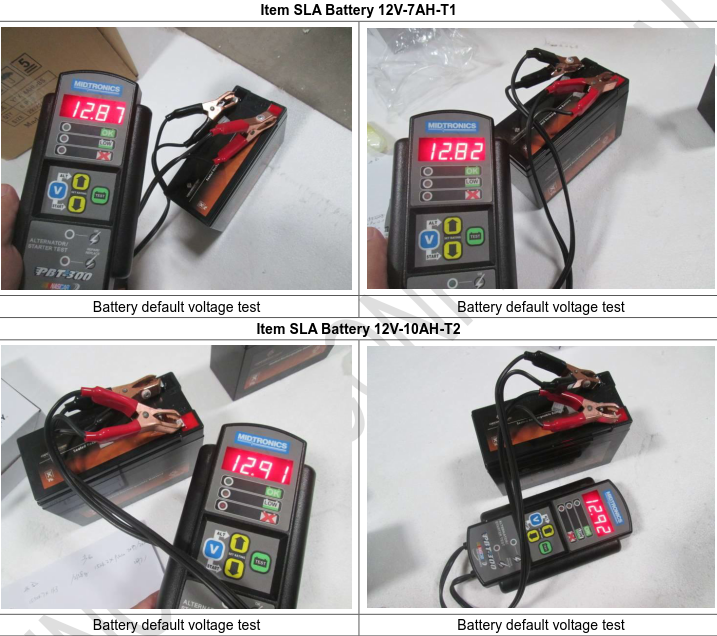

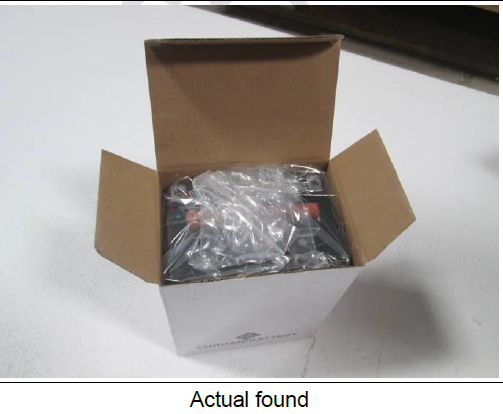

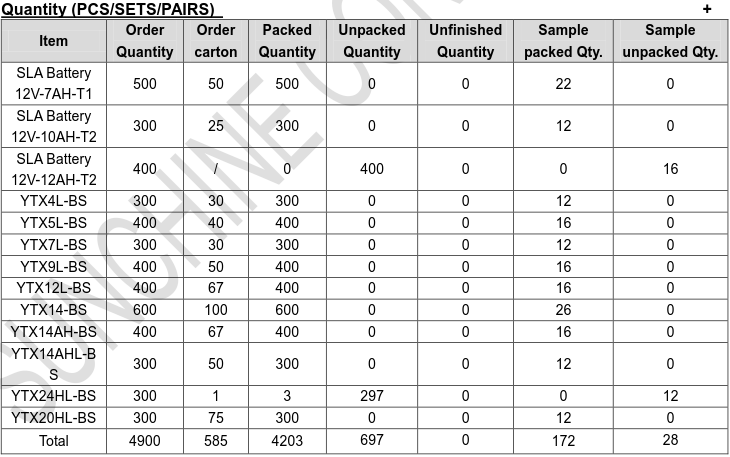

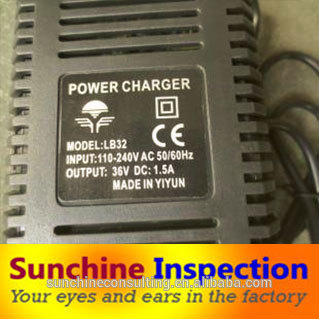

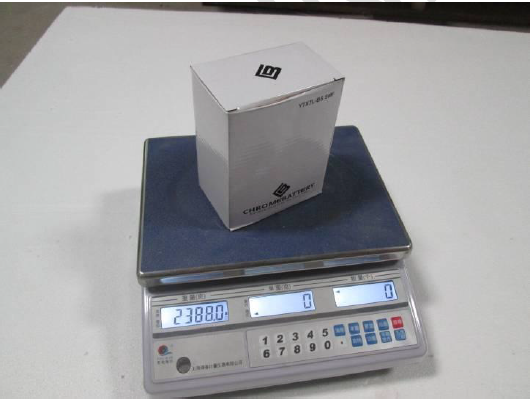

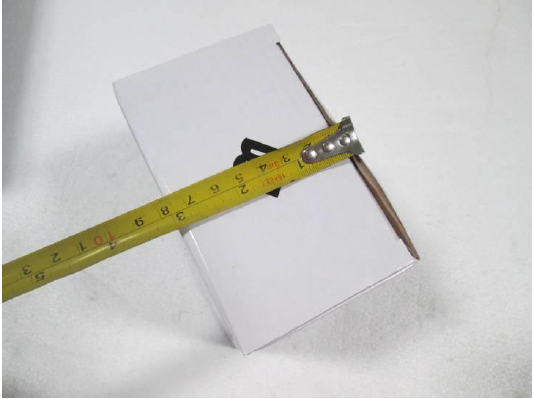

Some photos of the testing on product conducted by the full-time accredited inspector of Sunchine…

Battery Testing / Battery Checking Service Quality Inspector Control / Inspection Service

Relevant information:

Question: How can I develop quality inspection standards for a manufacturing process?

Answer 1: Quality inspection is important for the development of any manufacturer and their buyers as good quality is the basis to keep the long-term relation with clients.

Some of our clients ask third-party inspection company to check the quality before shipment ,personally we think it won’t help much as the production is almost completed and the inspection company can’t change anything except report the current situation of the bulk production,if any quality issue or error,that will still depend on the communication with seller and buyer.

As a qualified manufacturer,we will keep our clients updated on the process,if any mistake happened,we will be surely inform our clients first and discuss with them on the solutions.Production sample,Shipping sample will be always sent to the clients.If we want to maintain the relationship,we will be honest,loyal and do our best to control the quality,on the opposite,if someone won’t care about their reputation and spend few on QC,it may not help even the buyer stays in the workshop in person everyday during the production.

Simply speaking,it’s really important to select the right manufacturer for your projects. (Author: Daniel Lee From: Quora)

Answer 2: I’m assuming you don’t have industry standards you’re required to meet.

Check your contracts, because those are the standards you’re legally obligated to meet.(Author: Tamara Wilhite From: Quora)

This Post Has 0 Comments